ASTRA Rocketry Year 2

- Tony Wu

- Jul 29, 2025

- 2 min read

This year our team participated in ARC (American Rocketry Challenge, previously known as TARC). 1000 Teams across the US compete to build the best rocket with the top 10% qualifying for a nationals level bracket. The name of the game is to get a rocket as close to a specific altitude as possible within a specific time range. The close the max altitude is to the desired altitude and the closer the total flight time of the rocket is to the desired time range, better scores will be rewarded.

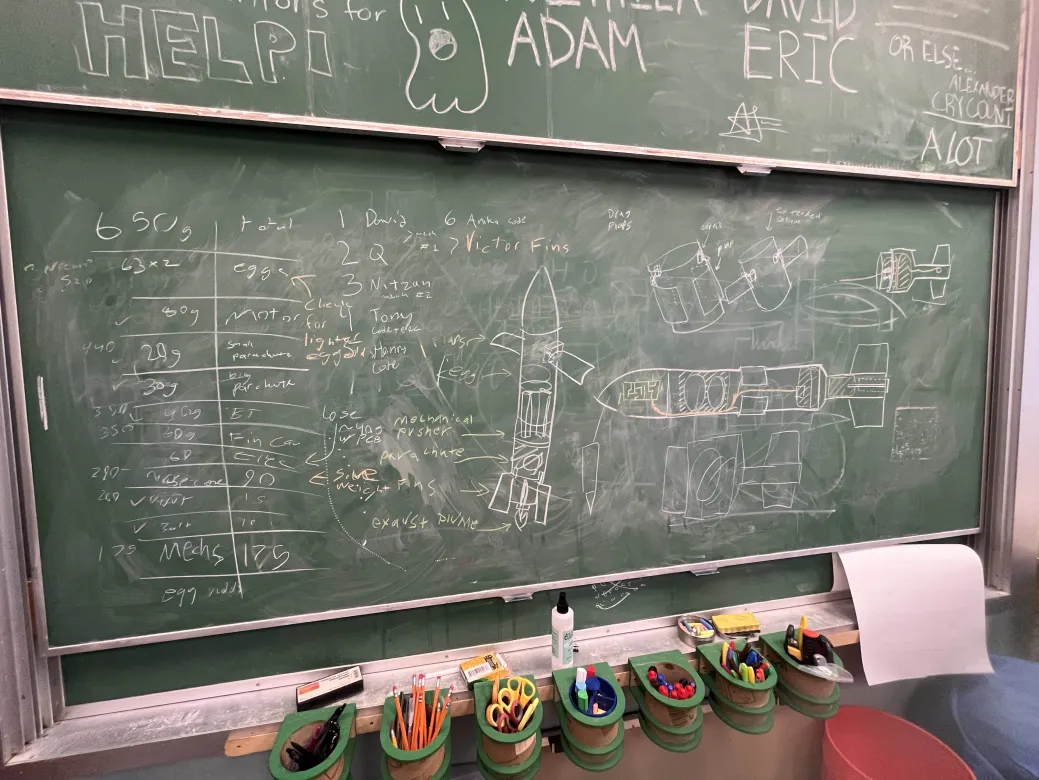

We opted for a advanced rocket with altitude control and time of flight control, this way with our limited model rocket launch opportunities we can achieve a better score. This was done through air brakes and a mechanical parachute deployment system.

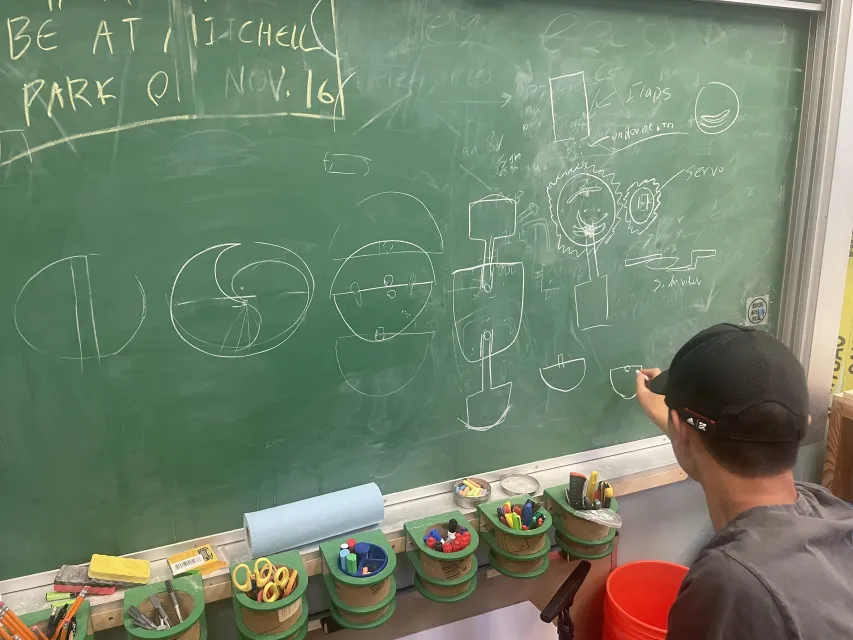

Airbrakes

Designed by Kyuhyun, The airbrakes we used focused on linkages and surface area to get the most drag out of the limited weight capacity we had.

We iterated a lot and went through many designs. Some were too complex, others too heavy.

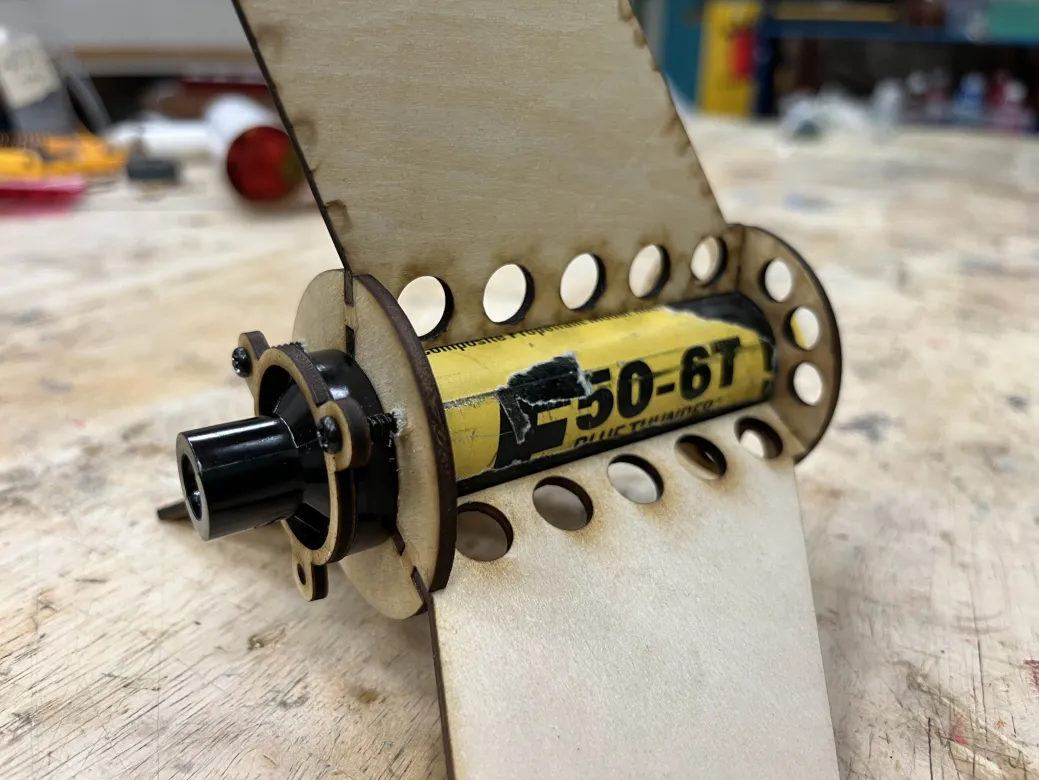

Parachute deployment

Our mechanical parachute deployment design was an accidental discovery. After playing around with parachutes, Henry found out a way to mechanically unreef a parachute using a single servo. This would allow two different descent velocities, simplifying the problem of flight time to a system of equations.

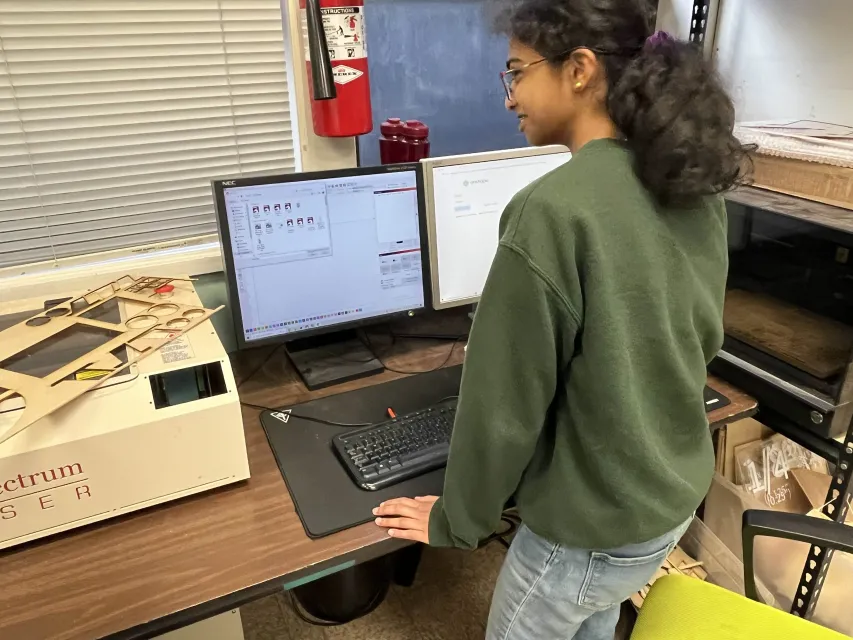

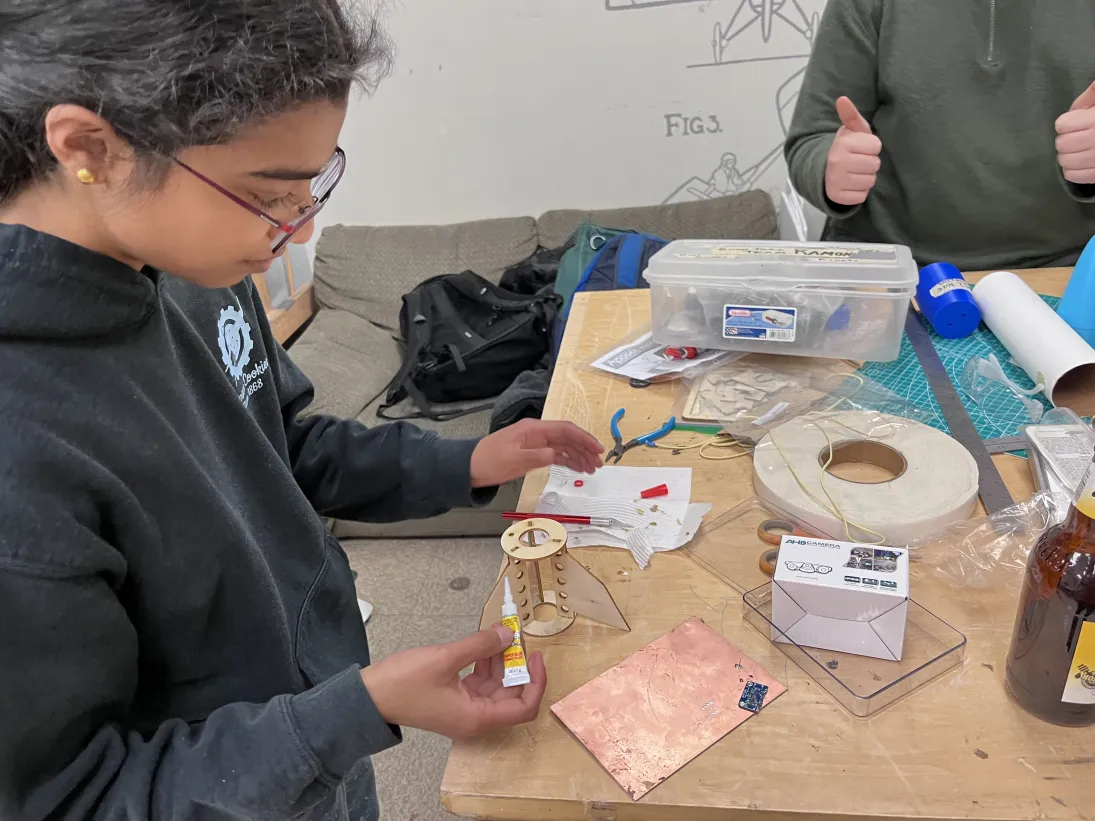

Flight Computer

We spent a lot of time developing a homemade flight computer after the rule changes allowing third party manufacturers to custom make printed circuit boards.

We started creating a custom designed printed circuit board. However it ran into many many issues and ended up scrapping the project.

Instead we switched to a more off the shelf solution finding hand soldering each connection. This was a more reliable solution

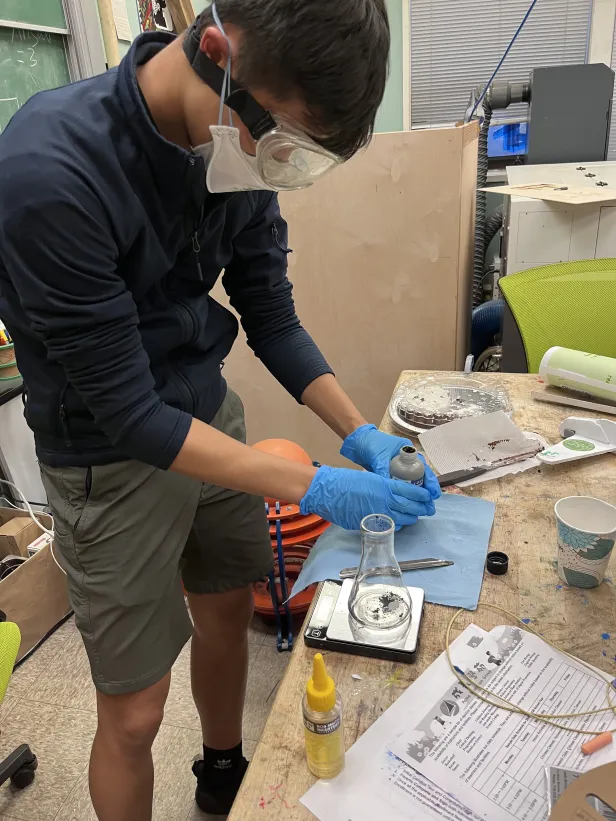

In the final month of the competition, our original copy of electronics got completely devastated. After our rocket flew into the ground, we decided to try another method of creating the electronics. Soldering connections is time consuming and frustrating, so instead we etched our own pcb and soldered it much quicker. This however came with it's own problems and we soon switched back to hand soldering right before the launch.

In the end we learned many lessons, some technical, most in time management. We barely qualified and our final launches failed spectacularly. Our motivation for next year is bigger than ever with many groundbreaking innovations in the making!